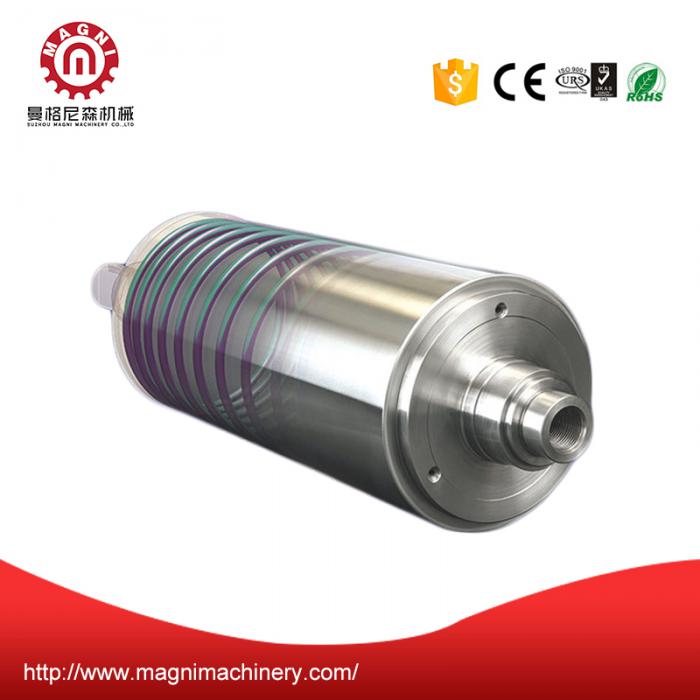

Cooling&Heating Roller with Spiral Channel

| Name: | Cooling&Heating Roller with Spiral Channel |

| material: | 20 steel |

| Journals: | 45 steel |

| Steel body: | Hard chroming thickness 0.03mm, 50~60HRC |

| Surface Roughness: | Rmax 0.4~ 0,8 µm - Polished |

Steel Cooling&Heating Roller with Spiral

Channel

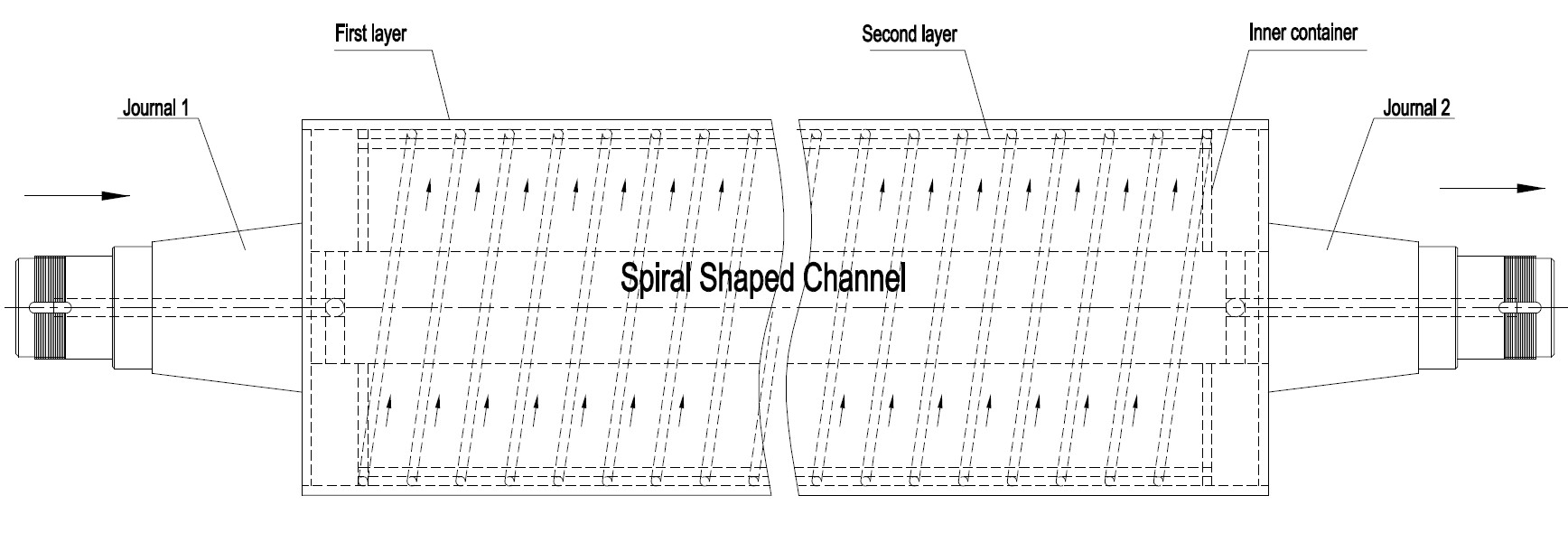

Double Shell with Spirals Passages

Structure: spiral flow channel will be consists of inner container ,two-layer and

three-layer sleeve pipe, spiral flow channel structure design, outer pipe hot

sleeve steel pipe, steel pipe outer surface polishing treatment, according to

customer demand can also be electroplated.

Processing: quenching and tempering with advanced heat treatment technology, fine turning

of the inner wall of the pipe, uniform wall thickness and small cooling

temperature difference, hot welding with interference heating installation,

annealing to remove stress, fine turning, grinding and polishing of the outer

pipe.

Usage:Cooling roller is widely used for cooling,

setting, cooling, calendering and compounding of various plastic film, paper,

sheet, plate, leather, metal, cloth and decorative materials.

The water cooling roller with three

inlet and three outlet structure is used for large cooling equipment, such as

wax cooling equipment.

Roller

maintenance

In order to prolong the service life

of the drum, the maintenance of the drum must be done well.

1. Clean the dust and other foreign

matters on the roller regularly.

2. Regularly check whether the welding

place between drum shell and end cover is firm.

3. Good lubrication, reduce the loss

of wear.

4. Avoid overload operation and

prolong the service life of drum.

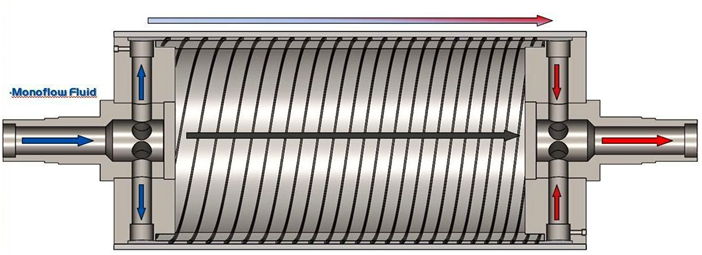

l In

this design, roll with inlet and outlet on opposite sides. The medium flows

through the roll, one side in and one side out.

l It

is most popular model

l Multi

start degressive or constant Spiral Baffles Section

l Mono

flow Fluid

l Medium

: Cold or Hot Water, Thermal Oil,

l Minimum

Pressure Drop and Temperature Variance, PERFECT temperature control

l Application

: Extrusion, Laminating, Coating, Stretching, Polishing, Embossing,

Calendering, special purpose to heating or cooling on the line...

Pictures of Roller and Rotary Valve